Referigerated Air Dryer

The Best Industrial Standard Refrigeration Air Dryers

Compressed air leaving a compressor often carries moisture, oil, and particles.

As the air cools, this moisture condenses into liquid water. Result?

This leads to rust, blockages, pitting, and freeze-ups. These issues can cause equipment failure and product rejection.

But we can help because our refrigeration air dryers reduce the dew point of compressed air by cooling it & then separating the condensate. This offers dry and clean air for industrial use.

What Are The Main Advantages of Our Refrigeration Air Dryers?

Protects Equipment:- It easily helps prevent rust, corrosion, and blockages in pipelines.

Minimises Failures:- It also helps avoid freeze-ups and damage to downstream components.

Supports Productivity:- It also helps to reduce downtime that often happens due to moisture-related issues.

Smooth Operation:- Not only this, but it also helps cool down compressed air to the lowest possible temperature for maximum water removal.

Working Principle of Refrigeration Air Dryer

When compressed air is cooled, the water vapour it carries condenses into liquid water. This can then be safely separated and removed.

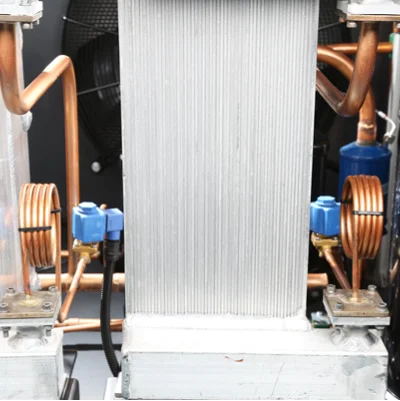

The heat exchanger is created with three functional sections:

Pre-Cooler (Air-to-Air Heat Exchanger): Incoming wet compressed air is pre-cooled by the outgoing dry, cooled air. This helps get a reduced amount of temperature of the wet air before final cooling.

Evaporator (Air-to-Refrigerant Heat Exchanger): The pre-cooled air helps further cool down the dew point. At this stage, the water vapour condenses into a liquid state.

Moisture Separator: The condensed water is separated and discharged through a drain port - no moisture remains in the air supply.

At last, the dry, cool compressed air passes back through the pre-cooler. Temperature regains normal before entering the distribution system.

The result is clean, dry air that highly minimises corrosion, blockages, & damage to downstream types of equipment.

Must-Know Exclusive Features of Our Refrigeration Air Dryers

The refrigeration air dryer is designed with advanced engineering that sets it apart from conventional dryers.

Microchannel condenser:

- The heat exchanger is created by us using high-performance fins and optimised geometry.

- Integrally fused fins help low down resistance, offering higher heat transfer rates.

- Offset fin design also helps with turbulence for improved heat exchange. Plus side? It also doubles as a preliminary moisture separator.

- A built-in wire mesh demister coalesces fine moisture particles.

- Not only that, but the microchannel condenser also offers cooling efficiency and helps cut down on energy use.

- Flat tube construction with microchannels maximises surface area and eliminates contact resistance.

- Comes with a parallel tube arrangement, which helps with easier airflow - lowering resistance and improving overall system performance.

- The dryers come with open-platform PLC control, and they also come with a monitoring system in real time that gives maintenance alerts.

- Electronic load tracking helps with sudden load changes.

- The step cooling technology keeps efficiency high, even at part load.

- The dryers also have smart flow control inside the exchanger.

PLC based control and protection

Open platform & fully customizable Elix Refrigerated air dryer... comes with an advanced open platform PLC with numerous features including total system monitoring, preventive maintenance alerts and compatible to industries required communication protocol such as RS485 modbus, BMS, IOT, Ethernet and Industry 4.0 etc. Being an open platform software, the PLC can be programmed to meet your specific requirements. Read More

Electronic Load tracking & Control

Instantaneous response to abrupt change in load Elixplus... Refrigeration air dryer keeps the Pressure dewpoint nearly constant even in wide operating range with quantum jump load variation with the help of electronically controlled capacity regulating valve (in selected model). Suction and discharge pressure transmitters ensure precise monitoring and control of process parameters. Read More

Step cooling to uplift the part load efficiency

Modular Cooler configuration & Integrated control... Flow characteristics play a vital role in improving efficiency of Heat transfer. At part load, the flow characteristics change drastically reducing the efficiency of Heat exchanger. Elixplus Modular Cooler configuration & Integrated control make use of Step cooling technology which effectively control the flow inside the cooler and keep the efficiency at higher level even at part load condition. Read More

Pacto Condensate drain valve

Silent Zero air loss, Ample savings. Zero air loss, Ample savings.

Range of Refrigeration Air Dryers

Series: Elix and Elixplus

Refrigeration air dryers

Capacity: 10cfm to 15000cfm

Pressure: 1 bar(g) to 16 bar(g)

Series: Elix VFD

Variable frequency drive refrigeration air dryers

Capacity: 400cfm to 15000cfm

Pressure: 1 bar(g) to 16 bar(g)

Series: Elix ECO

Refrigeration air dryers with R513A Eco-friendly refrigerant

Capacity: 10cfm to 15000cfm

Pressure: 1 bar(g) to 16 bar(g)

Series: Elix HP

High pressure refrigeration air dryers

Capacity: 10cfm to 600cfm

Pressure: 17 bar(g) to 250 bar(g)

| Class | Pressure Dew Point (°C) |

|---|---|

| 0 | As Specified By The Equipment User Or Supplier & More Stringent Than Class 1. |

| 1 | ≤-70 |

| 2 | ≤-40 |

| 3 | ≤-20 |

| 4 | ≤+3 |

| 5 | ≤+7 |

| 6 | ≤+10 |

Why Choose Us?

Opting for the right partner matters when it comes to air solutions. At Sontech, we combine expertise, scale, and most importantly, innovation to deliver lasting results.

Contact us today to know more about our Refrigeration Air Dryers.